Ultrasonic facilities for the ground materials characteristics control |

\\ Статьи

07/04/2014 2:49pm

Krivyi Rih National University, Krivyi Rih, 44 Pushkina Street, 50002, Ukraine

Abstract:The principal results of the technical facilities complex creating for ultrasonic control of the ground (milled) materials characteristics and adaptive systems for grinding (milling) and ore classification process control on its basis are presented.

Key words: Ultrasound, ore reduction, pulp solid phase, particles density.

Vladimir Morkun

Vice-Rector for research, Doctor of Science, professor of Computer Science, Automation and Control Systems department

Krivyi Rih National University

Natalia Morkun

PhD, Associate professor of Economic Cybernetics and Project Management Department

Krivyi Rih National University

Andrey Pikilnyak

PhD- student of Computer systems and networks department

Research Assistant of the Computer Science, Automation and Control Systems department

The ore reduction department is an intermediate element in mineral processing production line, but despite this it affects on the course of the following operations and final performance of the whole concentration plant.

The ore reduction operating costs during its benefication are about 50% which determine the final product cost price. Power consumption on ore reduction, depending on the initial ore quality and its final fineness within the limits of 55 % to 70 % of the total plant power [1].

Under the conditions of the feed ore characteristics and process equipment conditions changing the final performance of the ore reduction department significantly depend on the grinding and classifying units automatic control effectiveness which is primarily determined by the quality of informational and algorithmic support [2].

Thus replacement of the pulp density automatic stabilization system in the classifier overflow by the pulp solid phase autostabilization system on the basis of the granulometer allows to decrease the content variations of the crushed material control fraction from ±5 to 1,5 % and only due to this allows to increase the recovery of the useful component in the concentrate by 0,1-0,8 % [3].

Existing operational control facilities of qualitative and quantitative characteristics of ground material don't meet modern requirements.

The problems of control actions formation in the ore grinding-classification processes automatic control closed systems require the solutions. These systems allow to minimize the main technological equipment operation time in transitional regimes during which the qualitative and quantitative characteristics of the grinding cycle product output varies greatly[4].

In the R&D section of Krivyi Rih National University the theoretical basis for the ultrasonic testing of industrial suspensions main characteristics are developed [5, 6].

It was established that the weight percent of the pulp solid phase particle size control class definition can be carried out by measuring of two signals S1 and S2 the values of which can be determined by following expression [7]

![]() (1)

(1)

(2)

(2)

where ![]() and

and ![]() the intensity of the high frequency bulk ultrasonic oscillations which passed the distance z in pure water and pulp; I*lv and Ilv - the Lamb waves intensity at a distance of l from the source during the contact of pure water and pulp with the plate by which the Lamb wave propagate.

the intensity of the high frequency bulk ultrasonic oscillations which passed the distance z in pure water and pulp; I*lv and Ilv - the Lamb waves intensity at a distance of l from the source during the contact of pure water and pulp with the plate by which the Lamb wave propagate.

From (2) the value S2 is determined by the pulp solid phase concentration, and the relation between S1 and S2 characterizes the particle size distribution of the investigated medium.

, (3)

, (3)

where

The S value depends only on the particle size distribution and respectively defines the control size class concentration of solid phase particles. Furthermore, it does not depend on the the suspension gas phase content, i.e. in this case, the pulp pre-degassing is not required.

Several ultrasonic testing techniques of the pulp solid phase particles density and the extent of minerals disclosure (useful component) during ore reduction are proposed and investigated.

One of the proposed methods is based on the gamma-radiation and Lamb waves [8].

The mass attenuation coefficient of the gamma radiation by pulp can be presented in the following form

![]() , (4)

, (4)

where ![]() and

and ![]() are the mass attenuation coefficients of water and pulp solid component;

are the mass attenuation coefficients of water and pulp solid component; ![]() and

and![]() are the density of water and pulp solid particles; W - the volumetric fraction of pulp solid particles.

are the density of water and pulp solid particles; W - the volumetric fraction of pulp solid particles.

The amount of gamma-ray detector current is proportional to the radiation intensity I, therefore the S3 signal value at the output of the logarithmic amplifier is proportional to ln I.

The signal difference S3 and ![]() (

(![]() - signal in clear water), determined by the formula

- signal in clear water), determined by the formula

![]() , (5)

, (5)

where A – is the proportionality coefficient; l-is a distance between the gamma radiation source and its detector.

Similar difference in the channel of the Lamb waves SL is also proportional to the volume fraction of W.

The signals SL and Sγ relationship depends only on the mean density of solid particles

![]() , (6)

, (6)

where B is a proportionality coefficient.

A method of the useful component extent disclosure estimation, based on the preliminary test material sampling, in which the particle sizes are limited to a range from r1 to r2 is proposed. The selected sample is placed into the measuring vessel where the particles of the ground ore are freely deposited. At the depth of Z there is a measuring channel based on the volumetric ultrasonic oscillations.

The next signal is generated

, (7)

, (7)

where

,

,

N - is the number of particles;![]() - particle size distribution function according to the degree of useful component disclosing;

- particle size distribution function according to the degree of useful component disclosing;![]() - is step function that takes two values- 0 and 1, by negative and positive arguments resp.;

- is step function that takes two values- 0 and 1, by negative and positive arguments resp.; ![]() ; S- cross sectional area of the vessel;

; S- cross sectional area of the vessel;  ;

;  ;

; ![]() - is the density of particles with degree of disclosing

- is the density of particles with degree of disclosing![]() ;

; ![]() and

and ![]() - are the density of the useful component material and waste.

- are the density of the useful component material and waste.

It was established that the distribution function![]() can be evaluated according to the results of value St measuring by using the expression

can be evaluated according to the results of value St measuring by using the expression

![]() , (8)

, (8)

where ![]() .

.

As a perspective direction in the development of the grinding and classifying processes automatic control is using of adaptation algorithms based on the forming of pre-set characteristics of transient processes in the closed loop automatic control systems.

These algorithms provide for a preliminary identification of the static and dynamic process characteristics with subsequent correction of controller parameters according to the obtained estimations.

The transitional process begins when e.g. the reference value changes by the g-value in a closed loop automatic control system [9].

At its initial stage the PI regulator parameters correction carries out according to the following expressions

, (9)

, (9)

, (10)

, (10)

where  ;

;![]() ;K0 and T0 - are the static transmission factor and the process time constant, T— the time delay; tp - switch moment (correction);

;K0 and T0 - are the static transmission factor and the process time constant, T— the time delay; tp - switch moment (correction); ![]() and

and ![]() - are controllable coordinate and its first derivative.

- are controllable coordinate and its first derivative.

The current values of K0 and T0 determination is carried out according to the measured values of ![]() and

and ![]() at the initial stage of the transient process in the closed loop automatic control system.

at the initial stage of the transient process in the closed loop automatic control system.

Analysis of the developed algorithm applicability limits has shown that for the object, (which transient function is approximated by the product of two inertial components with time delay) the controller parameters correction is advisable under the condition when ![]() and the best correction results can be obtained by the switch from the condition

and the best correction results can be obtained by the switch from the condition ![]() .

.

To reduce the random noise influence on the correction results the controlled z(t)- signal digital filtering is carried out. This signal along with the useful component x(t) includes noise R(t).

Granulometer “Pulsar” is considered to be a basic device of the developed systems. It consists of three principal parts: Sample forming unit, electronic bloc and the estimator on the basis of micro-PC.

The sample forming unit serves for pulp sampling, stable flow forming within the ultrasonic measurement zone and its return to the technological process. The unit includes the measuring modulus and a sampling system with the elements of initial starting and self-regulating of the selected pulp samples amount. The measuring modulus is the device to form a directed pulp flow within the measurements zone. The piezoelectric transducers of the high frequency and forming prisms of measuring channel on the basis of Lamb-waves are fixed on the measuring modulus.

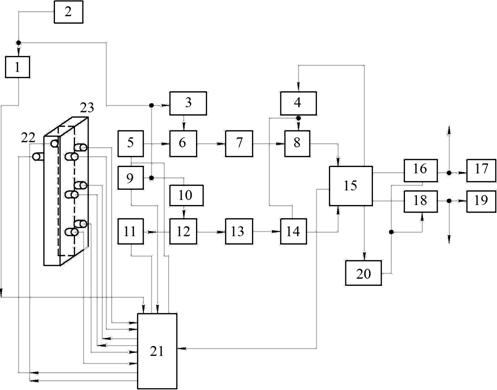

The simplified diagram of electronic block and estimator of the "Pulsar" granulometer is shown on the Fig. 1.

The following designations are listed in the block diagram: 1-9 - ultrasonic oscillations generators; 2- firing pulses formers; 3-10 - gating pulses formers; 4,20 - read-out pulses former; 5,11 - amplifiers; 7,13 - pulse transducers; 8,14 - analog-digital converters; 15 - micro-computer; 16,18 - digital-analog converters; 17, 19 - information mapping devices; 21 - switch for channel selection; 22 - measuring modulus on-line; 23 - measurement module (bearing).

Fig. 1. Block diagram of the ultrasonic granulometer ’’Pulsar”.

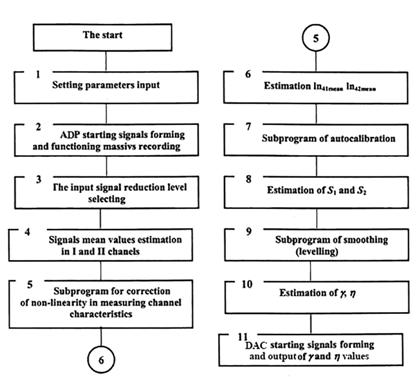

The basis algorithm elements for ultrasonic measurements of the solid phase concentration γ and content η of several ground material fineness grades in the pulp flow used in estimator of ’’Pulsar” granulometer are shown in the Fig. 2.

Fig. 2. Measurement algorithm block diagram of the ’’Pulsar” granulometer.

Conclusions

The production tests results and introduction of the developed test (control) facilities witness their high efficiency and this fact gives an occasion to recommend these facilities to wide utilization in the ore-mining enterprises.

References

- 1. Protsuto, Vladimir. Automated control systems of concentrating plants technological process. Moskow: Nedra, 1987.

2. Morkun, V., Goncharov, S., Pikilnyak, A., Krivenko, A. Iron ore benefication processes optimization. ТЕKA. Commision of Motorization and Energetics in Agriculture 12, no.4 (2012): 162-166.

3. Grinman, I., Blyakh, G. Control and regulation of ground product particle size distribution. Alma Ata: Nauka, 1967.

4. Morkun, Vladimir. Ultrasonic characteristics testing of crushed materials and ore crushing-classification processes adaptive control based on it. Dr. Sc diss., Krivyi Rih Technical University, 1999.

5. Morkun, V. Ultrasonic Control of Random Heterogeneous Mediums Parameters, AMMTIAC, no. 42(1992): http://ammtiac.alionscience.com/ammt/iacdocs.do?NT-49740

6. Morkun, V. Ultrasonic control of random heterogeneous mediums parameters.-Non Destructive Testing, ELSEVIER 92, (1991):989-993.

7. Morkun, V., Khorolsky, V., Protsuto, V., Potapov, V. Method and apparatus for measuring parameters of solid phase of slurries. Pat. 5058432 USA, MKI G 01 N 9/24. (Accessed. 22.10.91).

8. Morkun, V., Porkuyan, O. Lamb and Love ultrasonic surface waves in measuring systems. Krivyi Rih: KTU, (2006).

9. Morkun, V., Tsokurenko, A., Lutsenko I. Adaptive systems of technological processes optimal control. Krivyi Rih: Mineral, (2005)