Mathematical modelling of history of seamless pipes pressing |

\\ Статьи

The mathematical model of process of pressing of seamless pipes is developed and influence of different forms is set formative matrices on character of forming of energy power parameters of hearth of deformation. In interpretation of base variation of Euler’s task for the case of the direct pressing of pipes on the cylindrical mandrel the rational form of type (calibration) of matrix is certain.

Key words: pipe, technology, press, matrix, deformation zone, mandrel, model.

Suleiman Rakhmanov

National metallurgical academy of Ukraine,

theoretical mechanics department.

LLC "VOSTOK PLUS"

Mathematical modelling of history of seamless pipes pressing

Manufacturing operations of seamless pipes with usage of hollow billet pressing methodology in various modifications are based on the variety of physical peculiarities and technological advantages as compared with other methods of metal treatment under pressure [1].

It is known that while pressing of hollow billet there takes place the scheme of strained uniform compression in deformation zone, which is most advantageous from the point of view of increasing the values of metal workability. This provides high level of metal ductility, allows to deform the billet of low-ductile materials during single cycle of processing. The hypothesis is physical base for favourable conditions of hollow billet forming, especially from hard-to-deform alloys which are often subjected to crack formation (damage) during other deformation processes [2].

However, together with positive aspects, the processes of seamless pipes pressing have some disadvantages, which restrict the area of their usage. The most common among them are: low quality of service tool conditioned by its operation in bad conditions (high temperatures and critical contact voltages); relatively high metal consumption index, values of which, first of all, are determined by relatively high level of end pipe shearing [3,4].

Removal of disadvantages of pipepressing machines is possible through choice of effective process conditions of pipepressing processes, including grooving of reasonable processing tool (for example, matrix design).

Pressing process optimization of seamless pipes is based on the following groups of fundamental scientific researches and engineering developments: determining of the real deformation and speed parameters of pipe pressing; choice of effective geometrics of deforming instruments; selection of appropriate lubricants with optimal combination of antifriction properties; updating of press construction.

The main criteria of technological process optimization are minimization of energy-power parameters of hollow billet deformation process and increasing of single deformation of metals, that will lead to increase of presses productivity and accuracy increase of dimensions of pipes (hollow billet).

A lot of works are devoted to theoretical study of pressing process and pipe pressing in particular [1-6]. Let us analyze some works and mathematical models, where there is simultaneous analysis of stressed and deformed condition while seamless pipes pressing. For example, in work [3] there was a hypothesis, which stated that there is flat axial flow in the deformation zone. Such hypothesis obviously distorts true picture of hollow billet pressing process, as while realization of technological process there tales place critical velocity of metal flow gradient between points making contact with deforming tools and points, which are in the volume (central plies) of metal under press.

The most exact in basic view the task of pressing is represented in works [3,6], but while analysis of certain tasks there appear the range of difficulties, conditioned by the peculiarities of study of mathematical model of similar processes.

It should be marked that until now in literature there is no identical generalizing recommendations concerning choice of effective technological parameters of the process of pipepressing.

Below there is an attempt to get the refined mathematical model of seamless pipe pressing process, which is the closest to real processes, physical and boundary conditions of the task.

The main purpose of the proposed researches is getting the real image of distribution of energy-power parameters, development of generalized practical recommendations concerning choice of effective parameters of pipepressing process, design of service tools range and effective technological process of pipe manufacturing with the help of specialized presses.

Well-known methods of mathematical modeling of pressing processes, because of their peculiarities of deformable medium rheology, do not offer an opportunity for detailed analysis of dynamic peculiarities of technological processes of seamless pipes manufacturing.

In this case the usage of theoretical basis of continuum mechanics in interpretation of known class tasks of fluid-flow analogy allows to broaden the range of questions under consideration and solve some tasks concerning optimization the manufacturing process of seamless pipes with the help of extrusion press.

Considering that fact, that line-binding and viscoplastic medium models are proximal to real dynamic behavior of many metals, below is given the reason of fluid-flow analogy of deformation zone usage for study of pipe pressing process character. In this work adapted version of hydrodynamic model for fundamental research of dynamics of deformation zone and seamless pipe pressing process design is given. Further, for a first approximation, there observed the most common scheme of direct extrusion of seamless pipes on the extrusion press [1,5]. This scheme is the scheme of direct extrusion of seamless pipes, which supposes extrusion of hollow billet through ring-shaped channel formed by cylindrical mandrel and standardized die orifice.

Herewith pipe pressing process under this scheme is fulfilled as follows. Hollow billet heated to the necessary temperature (1200 – 1250ºС) is put to the orifice, then it is pressed with the help of ram through annular slit, formed by die orifice and cylindrical mandrel, forming pipe of desired geometry [1,3].

Let us assume the model of binding noncontractible operating environment with given viscosity factor ( medium rheology), which essentially depends on mechanical properties and temperature of hollow billet, as one of the successive refined mathematical models of metal flow while seamless pipe extrusion. Suggestions about appliance of such dynamic model but in other interpretation was proposed in the work [3], and practical usage of this model for determination of frictional force in deformation zone is fulfilled in work [4].

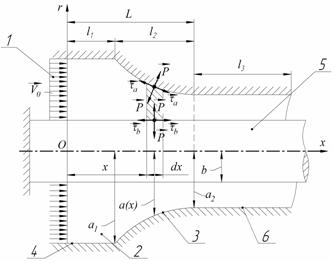

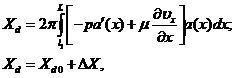

Let us consider the dynamic processes of seamless pipes extrusion on the pipe section press, design model of which is given in figure 1.

Figure 1. Design model of the processes of seamless pipes extrusion: 1 – ram; 2 – extrudable metal (hollow billet); 3 - die orifice; 4 – orifice; 5 – mandrel; 9 – press run-out chute.

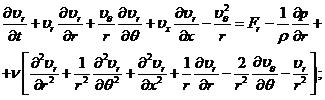

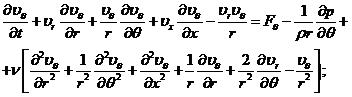

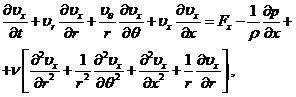

Viscoplastic medium dynamics, forming metal flow in deformation zone, let us consider axiosymmetrical. For research of dynamic processes in deformation zone let us use Navier-Stokes’ system of equations in cylindrical coordinate system. This equations [7,8] take the following form:

(1)

(1)

where![]() – are corresponding components of the velocity in the cylindrical coordinate system;

– are corresponding components of the velocity in the cylindrical coordinate system; ![]() – is pressure in deformation zone;

– is pressure in deformation zone; ![]() – components of body force;

– components of body force; ![]() ;

;![]() – viscosity of metal;

– viscosity of metal; ![]() – density of operating medium (of metal).

– density of operating medium (of metal).

Let us make some simplifying assumptions. We will consider that cross-section area of deformation zone, where monaxonic metal flow takes place, changes continuously, so we may ignore radial and tangential components of the speed ![]() and

and ![]() but not axial component

but not axial component ![]() .

.

Next, we will consider, that the pressing process runs rather slowly, so inertial component of the equation (1) (derivative ![]() )may be ignored. Besides, we will not take into account matching components of body force.

)may be ignored. Besides, we will not take into account matching components of body force.

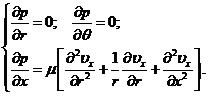

Under suggestions abovementioned the Navier-Stokes equations (1) are simplified and take on the following form:

(2)

(2)

Whence it follows that the pressure of metal in deformation zone is determined - function of disposal variable x.

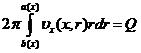

Equation of metal flow continuity we will depict as integrated equation of conservation of space velocity of operating environment in ring-shaped channel of deformation zone

It follows from the last equation, that the axial component of metal flow velocity in the zone ![]() in general terms strictly depends on coordinates

in general terms strictly depends on coordinates ![]() and

and ![]() , respectively, but taking into account the suggestion about continuous changing of cress-section area of deformation zone, taken by the metal flow, we will ignore the derivative

, respectively, but taking into account the suggestion about continuous changing of cress-section area of deformation zone, taken by the metal flow, we will ignore the derivative![]() as compared with other additive components in the on the right side of the equation (2). As the result we may form the modified equation of Navier-Stokes [8]

as compared with other additive components in the on the right side of the equation (2). As the result we may form the modified equation of Navier-Stokes [8]

(3)

(3)

This equation is the adapted variant of Poiseuille equation [7,8]. So, the considered hydrodynamic model of deformation zone is charecrerized by the fact that monaxonic pressed metal flow in each cress-section of deformation zone with sectional area ![]() ;is the same as Poiseuille motion in ring-shaped channel and the same fixed area. Solution of the equation (3) for axial metal flow in deformation zone in accordance with [8] is as follows:

;is the same as Poiseuille motion in ring-shaped channel and the same fixed area. Solution of the equation (3) for axial metal flow in deformation zone in accordance with [8] is as follows:

![]() (4)

(4)

where values ![]() and

and ![]() are not just arbitraty constants (as in case of Poiseuille motion), but they are some functions from

are not just arbitraty constants (as in case of Poiseuille motion), but they are some functions from ![]() coordinate, values of which are determined from the conditions of pressed metal and tool (on the mandrel

coordinate, values of which are determined from the conditions of pressed metal and tool (on the mandrel ![]() and orifice

and orifice ![]() ) cooperation on the corresponding area boundary of metal flow in deformation zone. Therefore, the common solution of Poiseuille equation (4) contains two parameters

) cooperation on the corresponding area boundary of metal flow in deformation zone. Therefore, the common solution of Poiseuille equation (4) contains two parameters ![]() and

and ![]() ,which is determined from boundary conditions of the matter. It is obvious that for viscid model of operating medium (of metal) boundary conditions of the matter are the conditions of cooperation of metal with processing tools, which are as follows

,which is determined from boundary conditions of the matter. It is obvious that for viscid model of operating medium (of metal) boundary conditions of the matter are the conditions of cooperation of metal with processing tools, which are as follows

![]() and

and ![]() (5)

(5)

Inserting the boundary conditions (5) into the expression (4) respectively, we will have two equations

![]()

![]()

where the values of required parameters ![]() and

and ![]() are determined

are determined

![]() (6)

(6)

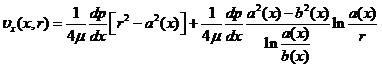

In result of (6) substitutions into (4) for axial component of metal flow velocity in deformation zone, we will have the following equation

(7)

(7)

where values ![]() and

and ![]() – are the corresponding die and mandrel radiuses (external and inner boundaries of deformation zone), which are the functions of

– are the corresponding die and mandrel radiuses (external and inner boundaries of deformation zone), which are the functions of ![]() ccordinate.

ccordinate.

In curvilinear ring-shaped channel with variable cross-sectional area limited by die ![]() and mandrel

and mandrel ![]() generatrices, velocity of metal flow

generatrices, velocity of metal flow ![]() is also taken the same as Poiseuille motion. In such a way, during solution of this task we use “Poiseuille’s hypothesis of local flow”.

is also taken the same as Poiseuille motion. In such a way, during solution of this task we use “Poiseuille’s hypothesis of local flow”.

One may see that formula (7) contains the value ![]() – pressure gradient, which is unknown in advance, but can be found out, if the value of metal outflow through the ring-shaped channel of deformation zone is defined or may be set experimentally. Judging from the hypothesis concerning incoercibility of pressing metal (of operating medium), output of operating medium in the ring-shaped channel of deformation zone equals

– pressure gradient, which is unknown in advance, but can be found out, if the value of metal outflow through the ring-shaped channel of deformation zone is defined or may be set experimentally. Judging from the hypothesis concerning incoercibility of pressing metal (of operating medium), output of operating medium in the ring-shaped channel of deformation zone equals

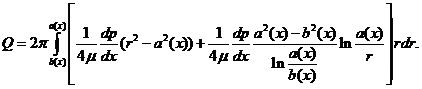

After integrating and some generations we will have

(8)

(8)

On the other hand, it should be marked that the value of metal usage ![]() expressed through the speed of ram motion in container

expressed through the speed of ram motion in container ![]() ,which is strictly defined by moving hydraulic power of the ram while pipe manufacturing process, and may vary in the course of pressing operation within some tolerance range of technical characteristics of press hydraulic system operating [2].

,which is strictly defined by moving hydraulic power of the ram while pipe manufacturing process, and may vary in the course of pressing operation within some tolerance range of technical characteristics of press hydraulic system operating [2].

![]() (9)

(9)

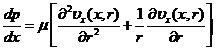

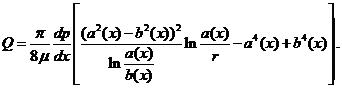

Than from (8) and (9) we will definitely get the expression for determining pressure gradient:

![]() (10)

(10)

where

.

.

It is obvious that in the function of operating medium outgo in the expression (10) must be (9). Consequently, the value of pressure gradient ![]() is proportional to expenditure

is proportional to expenditure ![]() of ram velocity

of ram velocity ![]() and viscosity factor of pressing metal μ, which is constant throughout the height of each section of deformation zone under consideration.

and viscosity factor of pressing metal μ, which is constant throughout the height of each section of deformation zone under consideration.

Herefrom follows that the pressure gradient (10) is the function of coordinate ![]() only. . Except that, metal pressure in deformation zone subsides from ran surface to field shapers (die and mandrel) because meridional radius of a die

only. . Except that, metal pressure in deformation zone subsides from ran surface to field shapers (die and mandrel) because meridional radius of a die ![]() subsides in the coordinate

subsides in the coordinate ![]() (figure 1). .

(figure 1). .

Let us denote the pressure under ram in the beginning of coordinates with the help of ![]() . Than the pressure

. Than the pressure ![]() in some section

in some section ![]() of deformation zone is determined

of deformation zone is determined

![]() . (11)

. (11)

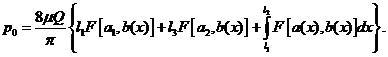

By virtue of the fact that in free cross-section (while metal fall) the upacting pressure is equal to zero, from the formula (11) we will have the following pressure ratings under ram:

(12)

(12)

Knowing the pressure under the ram ![]() , full pipe pressing power, which is necessary for providing predetermined rate of ram motion

, full pipe pressing power, which is necessary for providing predetermined rate of ram motion ![]() , we may determine as:

, we may determine as:

![]() (13)

(13)

It is characteristic that this force is proportional to ![]() , μand pressing characteristics.

, μand pressing characteristics.

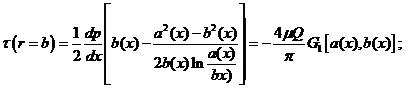

Experience of existing pipe pressing machines operation shows that in course of pipe pressing operations, both on the die and mandrel there appear great frictional forces [5]. In usual task approximating, according to the Newton law of viscous friction [7,8], in the pressing layer of metal there appear typical transverse strains

![]() (14)

(14)

Consequently, frictional constraint on the working surface of the mandrel ![]() equals

equals

![]() (15)

(15)

Then on the matrix generator we have

![]() (16)

(16)

Let us insert into (16) ![]() , deduced from the formula (7). Then we will get the final expression for determining and distribution of shearing stress on the mandrel and matrix respectively as:

, deduced from the formula (7). Then we will get the final expression for determining and distribution of shearing stress on the mandrel and matrix respectively as:

(17)

(17)

(18)

(18)

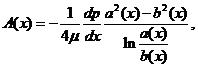

where  (19)

(19)

(20)

(20)

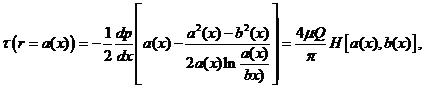

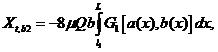

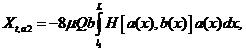

The expressions for determining transverse strains allow to calculate total frictional forces, affecting on mandrel and die in the deformation zone

![]() (21)

(21)

![]() (22)

(22)

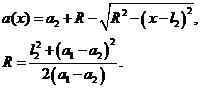

Let us consider the most commonly used geometry of borders of deformation zone in respect with the form, forming the die:

1. Die generator of conic shape.

![]()

2. Die surface of toroid shape.

3. Die generator of parabolic shape.

![]()

4. Die generator in the shape of cubical parabola.

Distribution of frictional forces along the length of working area of a die in respect with its generating form and mandrel are given on the figure 2 and 3. Typical friction resistance forces on the die and mandrel are divided into two additive components: the force ![]() , corresponding to the area with the length

, corresponding to the area with the length ![]() ( with constant container radius

( with constant container radius ![]() ) and the force

) and the force ![]() , corresponding to the area of a die and deformation zone (with the length

, corresponding to the area of a die and deformation zone (with the length ![]() and changing radius).

and changing radius). ![]() ).

).

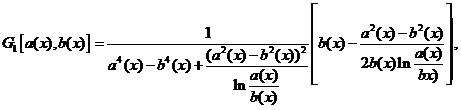

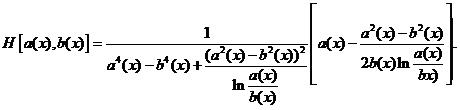

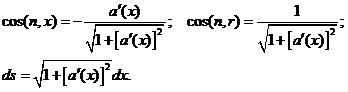

On the curvilinear area of working surface of the die and deformation zone, except transverse strains, values of which were determined previously, normal pressure forces are acting, which contribute to resistance of the mentioned area to flow of pressing metal. Strain on the area with normal

![]()

is equal to

![]()

and its X-component is equal to ![]()

![]()

Consequently, for strains![]() and

and ![]() respectively we have

respectively we have

![]()

If![]() – is the equation of die meridian, then

– is the equation of die meridian, then

Axial component of the force affecting the elementary area of carrier stream of pressing material is equal to

![]() (23)

(23)

It is obvious that from the side of pressing metal on the area ![]() the force is acting, which is opposite to (23) and is determined

the force is acting, which is opposite to (23) and is determined

![]() (24)

(24)

The expression (24) consists of two additive components, affecting the die: the first one acts by means of normal voltage ![]() ; the second one - by means of transverse strain, which was determined above. Due to normal voltage

; the second one - by means of transverse strain, which was determined above. Due to normal voltage ![]() (pressure forces) on the curved part of a die acts the force

(pressure forces) on the curved part of a die acts the force

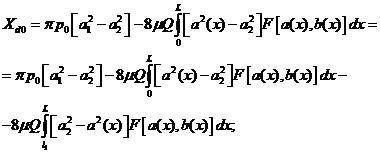

(25)

(25)

where

.

.

Inserting into (25) the pressure from (11) and expression ![]()

![]() from (7), we will find

from (7), we will find

(26)

(26)

(27)

(27)

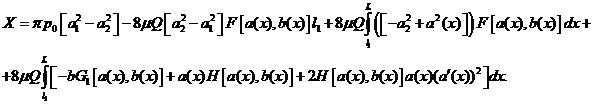

Consequently, the total force while pipe pressing process consists from frictional force on the corresponding area of mandrel cooperation with metal in deformation zone

(28)

(28)

and frictional force at the die area

(29)

(29)

pressure force (24) and secondary force (25) Then total resistance force at this areas of deformation zone is equal to

(30)

(30)

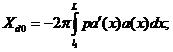

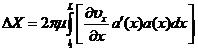

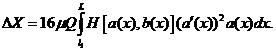

This force, as one may see from (30), depends on the form of generator of die working surface (equation ![]() ). This allows to set up the equation and solve variational problem appropriately: to find such shape of generator form of die working surface

). This allows to set up the equation and solve variational problem appropriately: to find such shape of generator form of die working surface ![]() , when the total resistance of working area would be the smallest if the length of deformation zone

, when the total resistance of working area would be the smallest if the length of deformation zone ![]() , maximum

, maximum ![]() and minimum radius

and minimum radius ![]() at the pipe output from deformation zone are defined.

at the pipe output from deformation zone are defined.

In the expression (30) the composite function, which depends on the equation forming dies ![]() , is the last integral, which after some transformations can be expressed as

, is the last integral, which after some transformations can be expressed as

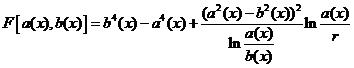

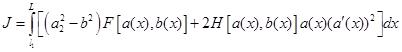

(31)

(31)

As subintegral function in (30) does not depend on the ![]() coordinate, the first integral of Euler equation [9] for composite function (31) will be the expression

coordinate, the first integral of Euler equation [9] for composite function (31) will be the expression

![]() , (32)

, (32)

where ![]() – is arbitrary constant.

– is arbitrary constant.

It is obvious that the equation (30), considering the composite function (29) is as follows

(33)

(33)

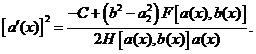

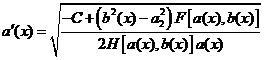

Proceeding from the position that there is fluent reduction in area of deformation zone ![]() , then from (33) we may state

, then from (33) we may state

. (34)

. (34)

For determining the equation of effective cross section of die working area (gage), constant ![]() , should be picked out in such way, that the gage element passed always through two places of its working surface known in advance

, should be picked out in such way, that the gage element passed always through two places of its working surface known in advance ![]() and

and ![]() .

.

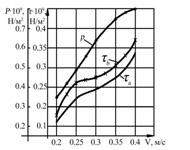

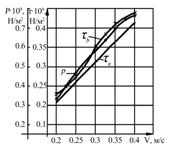

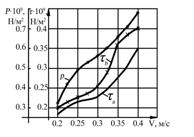

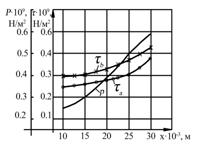

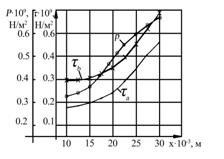

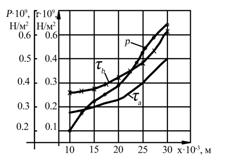

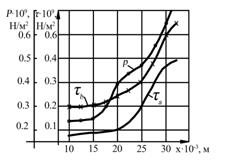

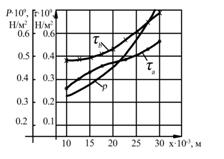

The results of solution of variational problem and differential equation (33), trough determination of effective cross section of die generator (gage) of 50MN pipe section press on the basis of original problem ( billet: material Х18Н10Т, 204х9 in diameter; diameter of a mandrel 186 mm; bloom: 196х9 in diameter) are given on the figure 2 and 3.

а) Cone b) Torus

c) Parabola d) Cubic parabola

e) Effective

Figure 2. Distribution of standard pressures ![]() , transverse strains on the die

, transverse strains on the die ![]() and transverse strains on the mandrel

and transverse strains on the mandrel ![]() in deformation zone in respect with the shape of die generator and velocity of pipe pressing process.

in deformation zone in respect with the shape of die generator and velocity of pipe pressing process.

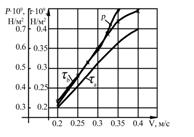

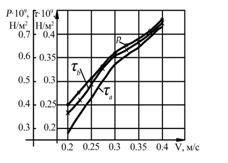

а) Effective V0=0.2 m/s b) Effective V0=0.25 m/s

c) Effective V0=0.3 m/s г) d) Effective V0=0.35 m/s

e) Effective V0=0.4 m/s

Figure 3. Distribution of standard pressures ![]() , transverse strains on the die

, transverse strains on the die ![]() and transverse strains on the mandrel

and transverse strains on the mandrel ![]() along the length of deformation zone in respect with the shape of die generator .

along the length of deformation zone in respect with the shape of die generator .

Conclusions

1. With the help of refining the mathematical model of deformation zone dynamics and strain-stress state of metal (operating medium), the possibilities for design and realization of augmented high speed manufacturing processes of seamless pipes pressing are determined.

2.The influence of various shapes of die generators and methods of pipe pressing on the formation of energy-power characteristics of deformation zone was discovered. Dependences, characterizing energy-power parameters of deformation zone and parameters of manufacturing process, for different shapes of die generators and methods of pipe pressing were formed.

3. With the help of mathematical modeling of pipe pressing process it was determined, that along the whole length of deformation zone with increase of metal flow velocity on the die and mandrel generator, that is of conic, torus, parabolic and cubic parabola shape, there is notable increase of transverse and normal strains. It should be marked, that for die generator that is in the shape of cubic parabola, these values lower than for others. With the increase of pressing velocity, energy-power parameters of deformation zone become of dynamic character.

4. The task concerning determination of effective cross-section (gage) of a die in the interpretation of Euler’s base variational problem for certain composite function of pipe pressing on the cylindrical mandrel is solved.

5.With the help of analysis of stressed state and pressing conditions of hollow billet, the ways for process optimization and upgrading of pressing pipes are nominated. Notable increase of working tools strength (dies and mandrels) is achieved.

References

- Danchenko V.N. Pipe and tube production technology. Textbook for universities. / V.N. Danchenko, A.P. Kolikov, B.A. Romantsev, S.V. Samusev. 2002 – 640p.

- Kolikov A.P. Machines and components for pipe and tube production: Textbook for universities/ A.P. Kolikov, V.P. Romanenko, S.V. Samusev, A.D. Sheikh-Ali, V.V. Frolochkin, - 1998. – 536 p.

- Gulyaev G.I Pressing of steel pipes and sections./ G.I. Gulyaev, A.E. Pritomanov, O.O. Drobich//1973. – 192 p.

- Gildengorn M.S. Treatment process of light and heat-resistant alloys. 1981. – 326 p.

- Perlin I.P. Theory of metal pressing - 1964. – 344 p.

- Gun G.L. theoretical science of metal treatment under pressure, 1980. – 456 p.

- Loitsyanskii L.G. Mechanics of fluids, 1978. – 736 p.

- Kochin N.E.,Kibel I.A. Roze N.V. Theoretical hydromechanics, part II, 1963. – 728 p.

- Gun G.L., Yakovlev V.I. Mathematical modeling and optimization, 1974. – 336 p.